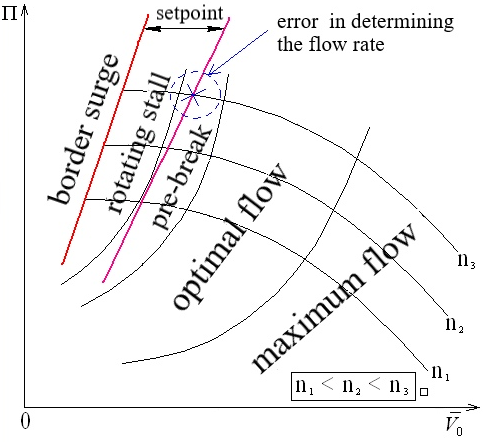

The article deals with the problems of diagnostics of surging phenomena in centrifugal compressors. The reasons for the surge phenomenon and the method for its diagnosis to prevent emergencies are stated. The article describes the phenomenon of rotating stall, which precedes the surge. Diagnostics of the appearance of a rotating stall opens the possibility of predicting the appearance of a surge. This allows for an efficient and safe surge protection system. Solving the problem of developing new principles for constructing surge diagnostics systems. Application of biorthogonal wavelet transform for prebreak detection.

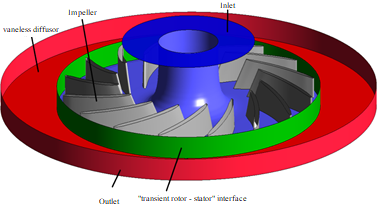

Virtual testing unit description for unsteady flow phenomena investigations in a centrifugal compressor based on ANSYS 12.0 system is presented. Comparisons of calculated and experimental results for steady and unsteady data are acceptable. Transient Blade Row methods (the CFX Transient Blade Row Modeling with the terminology of Turbo component) — is the sector of blades in a given blade row that are being modeled in the analysis. Transient Rotor-stator analyses involve at least two components, one rotating and one stationary component

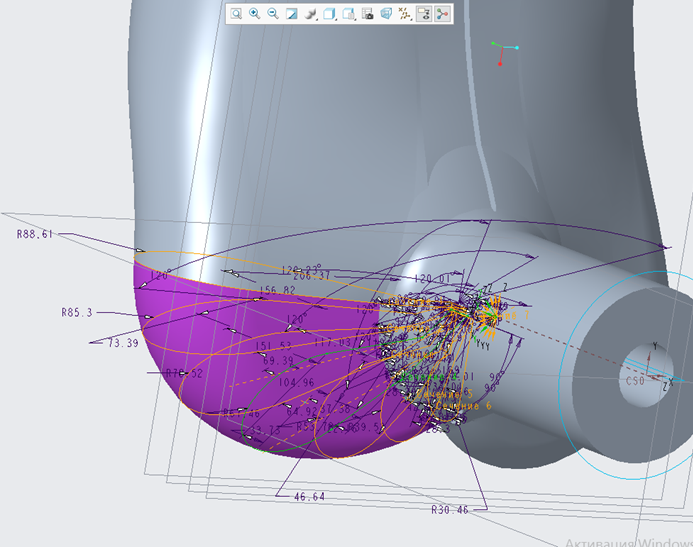

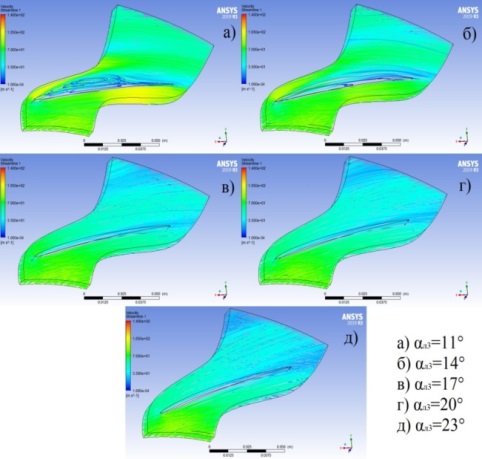

Efficient compressors designs reduce the overall energy consumption of industrial buildings. The inlet chambers for turbocompressors have a significant influence on the whole stage operation. An uneven flow in the inlet of an impeller can turn up to be the cause of stage efficiency drop, and also it is able to narrow down the range of its operational stability which in turn is an essential negative factor. Currently, there is no clear methodology of the design of the inlet radial chambers which makes it difficult to design the compressor. The purpose of this work is to develop recommendations for the designing problem formulation of the centrifugal compressor radial inlet chamber and also modify the existing design method for inlet chambers. During the previous research, the most acceptable model of the inlet chamber was obtained with the help of real and numerical experiment. In this paper, different geometric parameters of the inlet chamber are changed and then calculated by means of numerical experiment. Their influence on the inlet chamber loss coefficient, relative velocity distribution and static pressure coefficient is investigated.

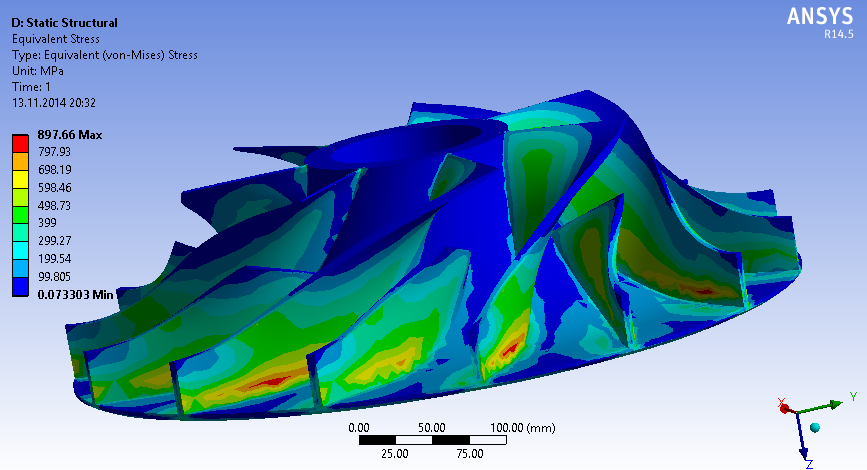

The article deals with the issues of the 3D impellers strength analysis for the different centrifugal compressors. Two air compressors are considered, the first for General industrial use, the second for turbocharging the internal combustion engine. The third compressor is designed for the turboexpander unit that operating at high pressure medium. The materials of the impellers were steel, titanium and aluminum alloys. The expediency of using the Fluid-Structure Interaction approach for the strength analysis is considered for these compressors. With the FSI approach, a coupled CFD-FEA solution is performed. Gas-dynamic forces from the medium pressure are taken into account in the impeller strength or vibration analysis. The Ansys package is selected as the program for analysis. CFD models are built and configured in the Ansys CFX. The FEA solution carried out in the Ansys Static structural. The results of strength analysis are compared with and without pressure forces for all impellers. As a result, there were no significant differences in the two solutions for the air compressors. However, for high-pressure compressors, the results of the coupled solution showed the need to take into account the CFD solution. Based on the obtained data, a graph of the reliability coefficient dependence on the increase in the suction pressure in the range from 1 to 100 bar is plotted.

Computational fluid and gas dynamics methods are used at all stages of design, including blade machine design: from the creation of a schematic design to a detailed study of all the main units [1, 2]. The industries using refrigeration centrifugal compressors (oil refining, chemical, food) development requires the machines unit capacity, efficiency and reliability increase, the weight and size characteristics and metal consumption decrease. Since this machine type production often has a small-scale or individual character, and the needs for machine specified characteristics maintain during the entire service life exists, design remains an important stage in the creation process. This article is devoted to the possibility of validating the calculations using the numerical gas dynamics methods research. The centrifugal compressor end stage numerical and a full-scale research were made during the investigation; refrigeration centrifugal compressor end stage full-scale investigation carried out by D.A. Kapelkin was chosen as a base of the research [3]. As a result, the diffuser flow numerical simulation results were analyzed and the calculated and full-scale characteristics comparison was carried out. Recommendations for the numerical gas dynamics methods application are given in a particular case, applied to refrigeration centrifugal compressors vane diffusers gas-dynamic calculations.